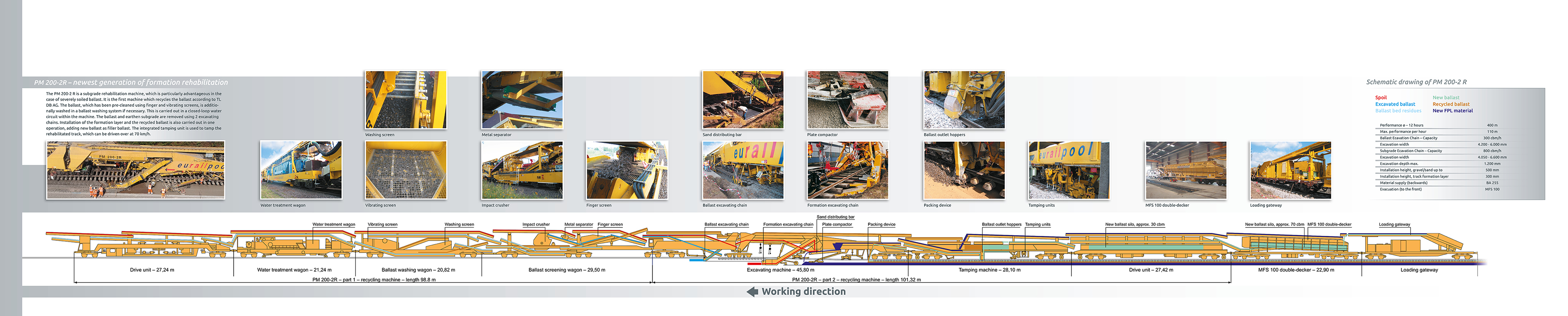

PM 200-2R

Newest generation

of formation rehabilitation

The PM 200-2 R is the newest formation rehabilitation machine with integrated ballast recycling currently in operation in Europe. It is the first machine which offers the option of washing the ballast, which has been pre-cleaned using finger and vibrating screens, in the case of extremely cohesive ground conditions. This is carried out by means of a closed-loop water circuit within the machine. The ballast and earthen subgrade are removed using 2 excavating chains. Installation of the formation layer and the cleaned, recycled ballast, which is washed if necessary, is also carried out in one operation, adding new ballast as filler ballast. The integrated tamping unit is used to tamp the rehabilitated track, which can be driven over at 70 km/h.

| Performance ø in 12 hours | 400 m |

| Max. performance per hour | 110 m |

| Ballast Excavation Chain - Capacity | 300 cbm/h |

| Excavation width | 4.200 - 6.000 mm |

| Subgrade Excavation Chain - Capacity | 800 cbm/h |

| Excavation width | 4.050 - 6.600 mm |

| Excavation depth max. | 1.200 mm |

| Installation height, gravel/sand max. | 500 mm |

| Installation height, track formation layer | 300 mm |

| Material supply (backwards) | BA 255 |

| Evacuation (to the front) | MFS 100 |