Menu

PM 1000 URM

The new standard in

subgrade rehabilitation

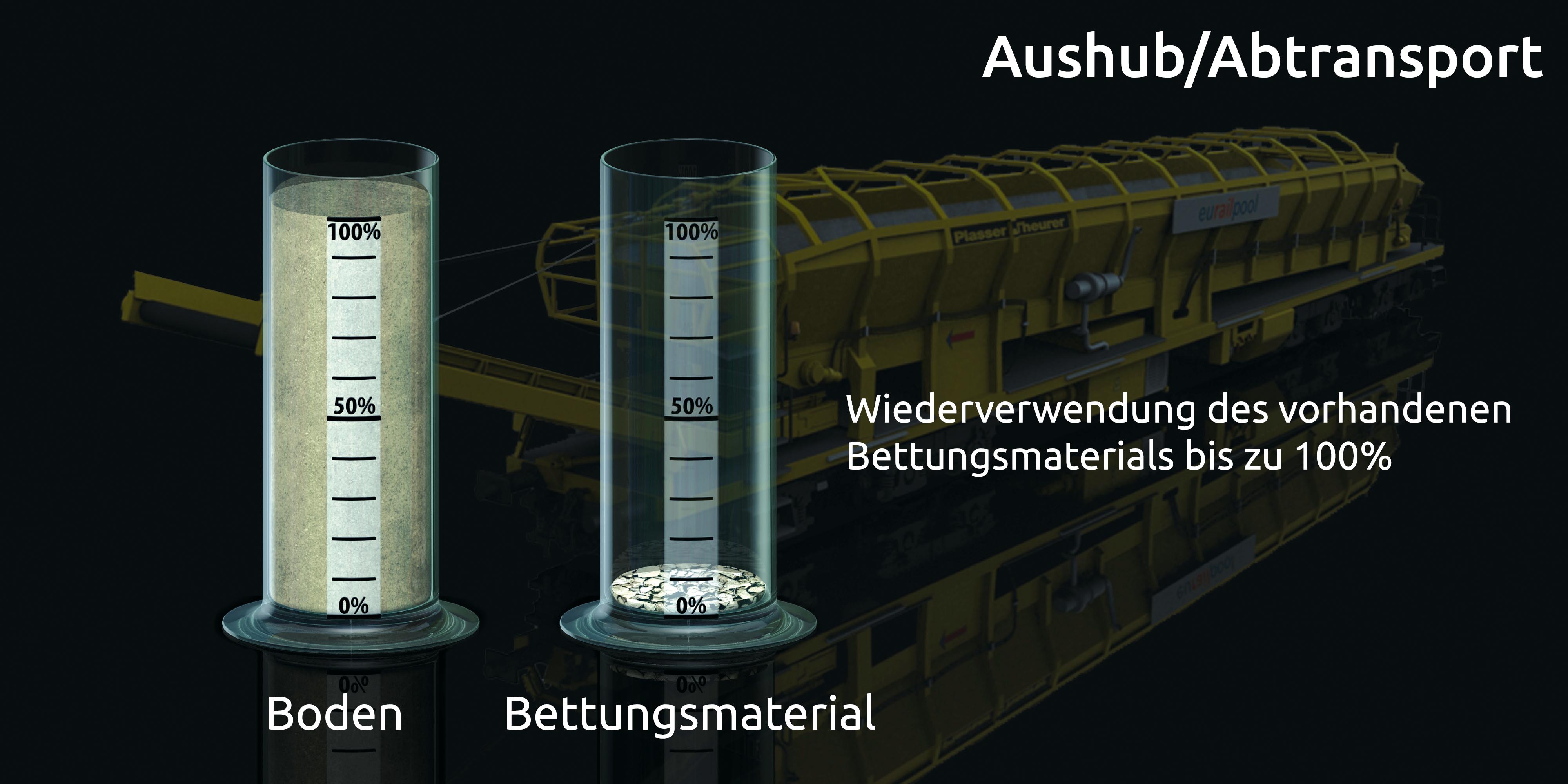

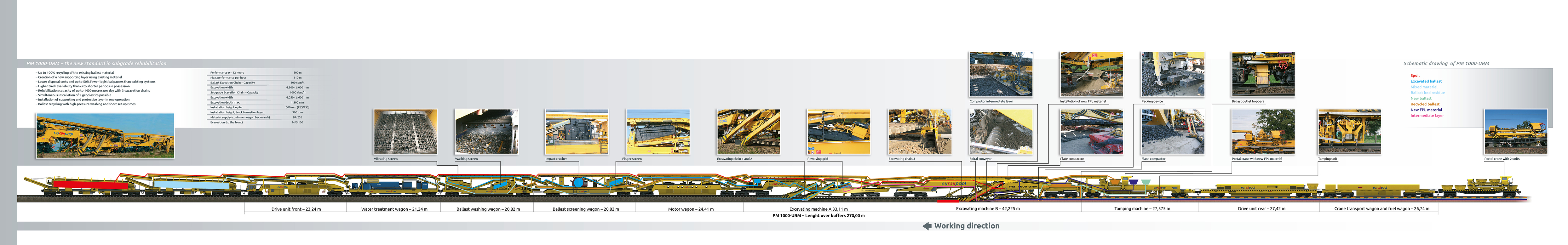

- Up to 100% recycling of the existing ballast material

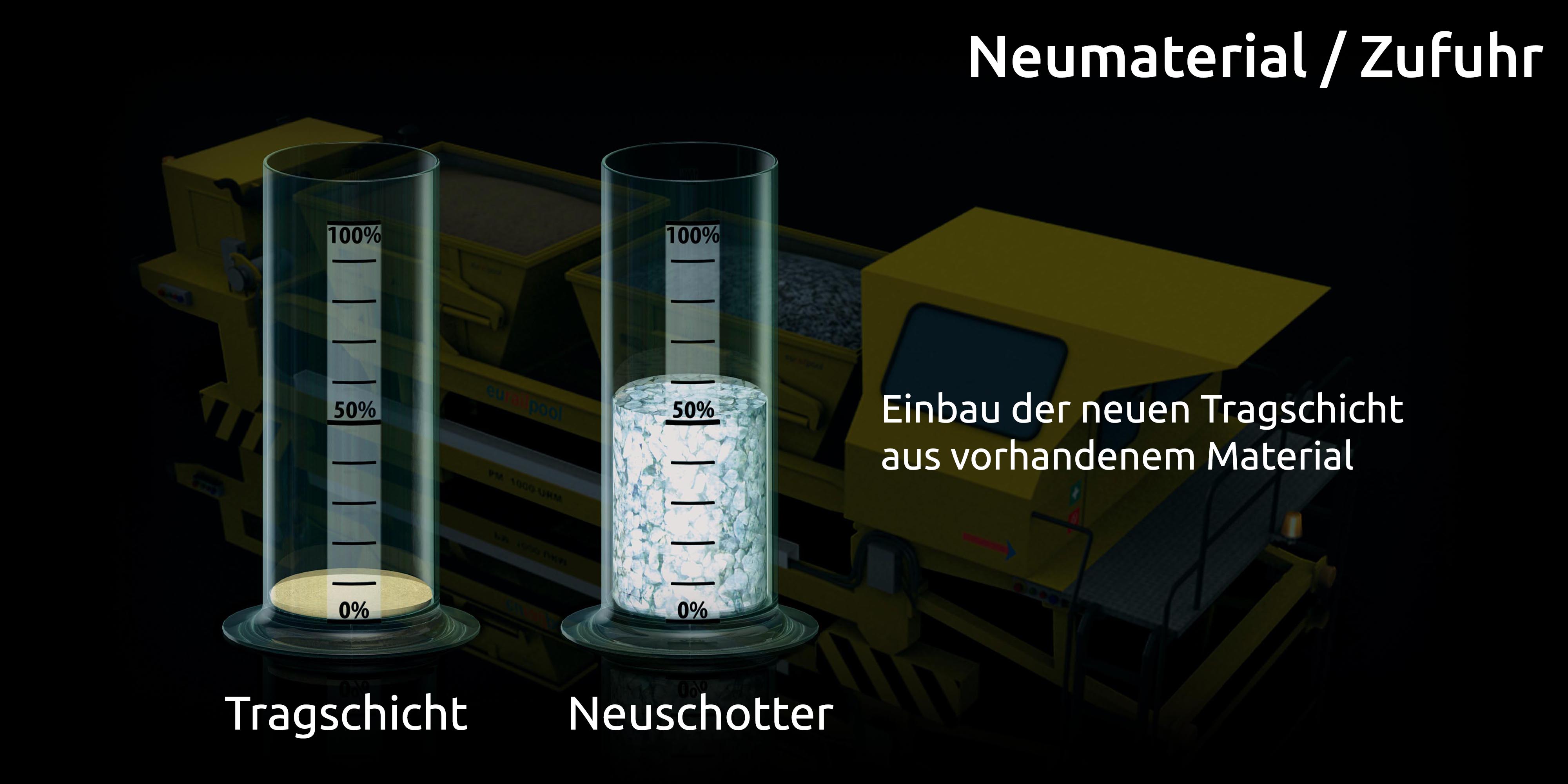

- Creation of a new supporting layer using existing material

- Lower disposal costs

- Up to 50% fewer logistical pauses than existing systems

- Higher track availability thanks to shorter periods in possession

- Rehabilitation capacity of up to 1400 metres per day

- 3 excavation chains

- Simultaneous installation of 2 geoplastics possible

- Installation of supporting and protective layer in one operation

- Rehabilitation capacity of up to 120 m/h and up to 1400 m/day

- Ballast recycling with high-pressure washing

- Short set-up times

| Performance ø – 12 Hours | 500 m |

| Max. performance per hour | 110 m |

| Ballast Ecavation Chain – Capacity | 300 cbm/h |

| Excavation width | 4.200 - 6.000 mm |

| Subgrade Excavation Chain – Capacity | 1.000 cbm/h |

| Excavation width | 4.050 - 6.600 mm |

| Excavation depth max. | 1.300 mm |

| Installation height up to | 600 mm (PSS/FSS) |

| Installation height, track formation layer | 300 mm |

| Material supply (container wagon backwards) | BA 255 |

| Evacuation (to the front) | MFS 100 |